The Role and Working Principle of Protein Skimmers in Recirculating Aquaculture Systems

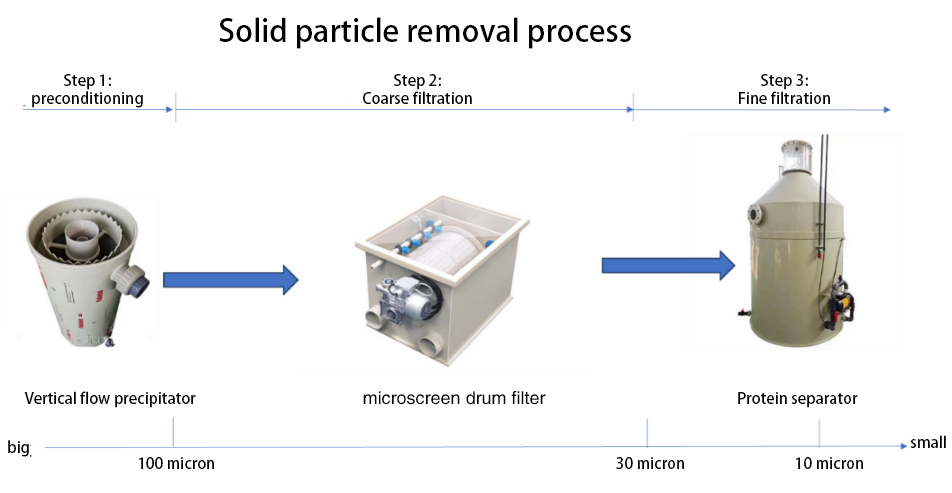

Solid suspended particulate matter has adverse effects on various aspects of land-based industrial recirculating aquaculture systems, therefore, removing solid suspended particulate matter is the primary goal of recirculating aquaculture treatment. The majority of particles in the circulating aquaculture system are smaller than 100 microns in size. Due to factors such as water turbulence, biodegradation, and mechanical agitation, suspended particles that cannot be removed in a timely manner will break down into smaller particles, typically less than 30 microns in size. In this case, sedimentation treatment and mechanical filtration will become ineffective.

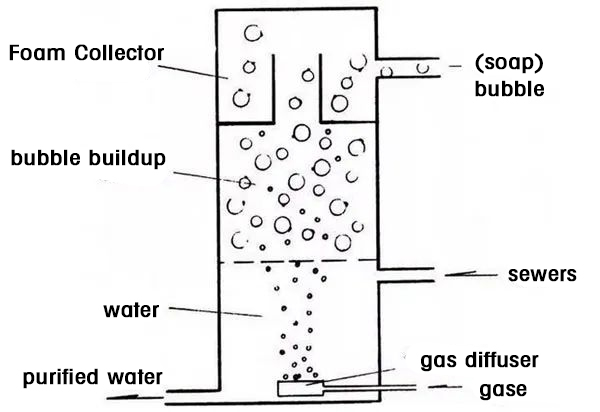

Foam separation technology is a technology used to remove fine suspended particles. By introducing air into the water body, the surfactant in the water is absorbed by tiny bubbles, and then rises to the water surface with the buoyancy of bubbles to form foam, so as to remove dissolved and suspended substances in the water. At present, foam separation is considered as one of the main processes to effectively remove micro particles in the recirculating aquaculture system, and is an important part of the recirculating aquaculture system.

Principle of Protein Skimmers

1. Foam Fractionation Principle

The protein separator is mainly based on the principle of foam separation. In a recirculating aquaculture system, due to the presence of a large amount of organic matter in the excrement and residual feed of aquaculture organisms, surface active substances such as proteins in these organic matter have amphiphilicity (both hydrophilic and oleophilic). When a large number of tiny bubbles are introduced into water, these surface active substances will adsorb onto the surface of the bubbles. With the rise of bubbles, the bubbles with protein and other substances adsorbed on the surface form a foam layer on the water surface. The density of the foam layer is small, and it is easy to separate from the water body, thus removing organic matters such as protein in the water.

2. Physicochemical Process

From a microscopic perspective, there is surface tension between bubbles and water. When bubbles rise in water, organic molecules in the water will aggregate towards the surface of the bubbles under the action of surface tension. This is a physical adsorption process, accompanied by some chemical changes such as interactions between organic molecules and chemical reactions with the surface of bubbles. For example, some protein molecules may undergo denaturation, making them easier to adsorb onto bubbles.

The Role of Protein Skimmers in Recirculating Aquaculture

(1) Water Purification

1. Remove organic matter

Protein separators can effectively remove organic matter from water, including proteins, fats, sugars, etc. If these organic compounds accumulate in water, they will be decomposed by microorganisms, consuming a large amount of dissolved oxygen and producing harmful substances such as ammonia nitrogen and nitrite. Removing these organic compounds through a protein separator can alleviate the pressure of subsequent biological filtration and reduce the production of harmful substances in water. For example, without a protein separator, the chemical oxygen demand (COD) in water may rapidly rise to over 100mg/L, while with the use of a protein separator, COD can be controlled at around 30-50mg/L.

2. Reduce the production of ammonia nitrogen

Due to the removal of nitrogen-containing organic compounds such as proteins by the protein separator, the potential source of ammonia nitrogen in water is reduced. This is crucial for maintaining a low concentration of ammonia nitrogen in the recirculating aquaculture system, as ammonia nitrogen has strong toxicity to aquaculture organisms.

(2) Improved Water Clarity

The protein separator can not only remove organic matter, but also carry away suspended particles with a particle size of less than 30 microns in the water, improving the transparency of the water and promoting the growth of aquaculture organisms.

(3) Reduction of Disease Transmission

Removing pathogen carriers: Organic matter and suspended particles in water are often carriers of pathogens, such as bacteria, viruses, and parasites. The protein separator removes these carriers, which reduces the chance of pathogen transmission in water and lowers the risk of disease infection in aquaculture organisms.

Tel.: +86 17864390557