Aquaculture one-stop solution provider & liquid storage equipment manufacturer.

Guide to Buy Recirculating Aquaculture System in WOLIZE

Shandong Wolize Biotechnology Co., Ltd. never hesitates to promote recirculating aquaculture system to global market in the post-industrial era. The product is manufactured adhering to 'Quality always comes first', so a professional team is allocated to ensure material quality and promote the R&D process. After repeated trials and tests are conducted, the product successfully has its performance improved.

We have been strengthening our local R&D capability to design and localize our products in the overseas market to cater to the local people's needs and has succeeded in promoting them. Through those marketing activities, the brand influence of our brand -WOLIZE is highly increased and we glory in allying with more and more overseas enterprises.

We encourage our employees to take part in the training programme. The training is designed to cater to different job requirements and the individual situation on the issue of research and development experience, handling with customers' problems, and the latest development of the industry. Thus, by providing specific training, our employees can provide the most professional advice or solution for customers at WOLIZE.

1. What is flow-through aquaculture?

Flow-through aquaculture is intensive, high-density intensive aquaculture in artificially controlled water bodies, which has the advantages of short cycle, fast growth, high yield, high efficiency and high commercial rate. Flow-fed fish farming generally increases production by about 40% compared with conventional fish farming, and is an emerging aquaculture technology worth promoting. The development of fish farming is promising, firstly, as long as there are reservoirs, rivers, mountain streams and other water resources, as long as the conditions are created for fish farming; secondly, the water flowing out of fish ponds can still be used for irrigating farmland, so as to achieve the multi-purpose use of one water, without wasting water resources.

2. How to choose the address for flow-through aquaculture?

Flow-through fish ponds require sufficient water sources, good water quality, stable water level, suitable water temperature, and water temperature between 15-30℃ between May and October. Requirements for adequate sunlight, high dissolved oxygen, feed and fish species supply convenience. Fish ponds are best built in a natural drop, and can be cited in reservoirs, irrigation canals can flow, water streams and water volume of self-flowing near, or choose to build in the non-polluting, year-round mountain springs next to the water system, or choose to build in the vicinity of the power plant, the use of waste hot water running water. Being able to utilize these running waters for fish farming can reduce production costs and improve economic efficiency.

Our Aquaculture System: A Perfect Balance of Environment and Technology

As humans, it is our responsibility to take care of our planet and ensure our actions do not have a impact negative the environment. same we also want to maximize our resources and use technology to our advantage at the time. At our wolize company, we have found a solution to this problem nagging our aquaculture system. Here are some of the advantages, innovations, and applications of our system, as well as instructions on how to use it and information about our quality and service.

Advantages of Our System

Our aquaculture system has advantages are several including being efficient and eco-friendly. It has been designed by us to conserve water and reduce waste. This means we use less water and produce less waste than traditional aquaculture methods, which good for both the environment and our business.

Another advantage our system designed for easy use. You don't need to be an expert to use it, and it is customizable to fit your needs. With this operational system, you can grow fish, shrimp, and other creatures are aquatic and efficiently.

Innovations in Our System

We have incorporated the latest technologies into our aquaculture system to make it the most innovative in the market. One of the most innovations are important the use of artificial intelligence to monitor and maintain the system. The aquaculture industry system can detect any problems or changes in the water quality and take action corrective intervention human.

The system also includes automated feeding, which means the fish and shrimp are fed at the time right in the right amount to eliminate waste and improve efficiency. Finally, our system includes a biofilter removes waste from the water and ensures the water quality remains optimal for the creatures are aquatic grow.

Safety of Our System

We take the safety of our customers seriously, which why our system designed to be safe and easy to use. The aquaculture solution materials we use to build the operational system are high quality and safe, and we follow strict safety standards in our manufacturing process.

In addition, we offer training to our customers to ensure they know how to use the system operational. We also provide ongoing support and maintenance to ensure the operational system functioning properly and safely.

How to Use Our System

Using our aquaculture system straightforward and easy. First, you need to set the system up in a suitable location. Once the system set up, you can fill it with water and start fish adding shrimp, or other aquatic creatures.

The system automated, which means the feeding, monitoring, and maintenance are all taken care of by the system. However, you still need to monitor the operational system and make sure everything working properly.

Service and Quality

We pride ourselves on the quality of our system and our commitment to customer service excellent. Our system built to last, and we use only the quality materials are highest in its construction.

In addition to our quality products, we also provide excellent customer service. We offer training and support ongoing ensure our customers are satisfied with their purchase and their system functioning properly.

Applications of Our System

Our aquaculture system has a wide range of applications in the food industry, including fish farming and aquaculture farming shrimp. It can also be used in education and research projects.

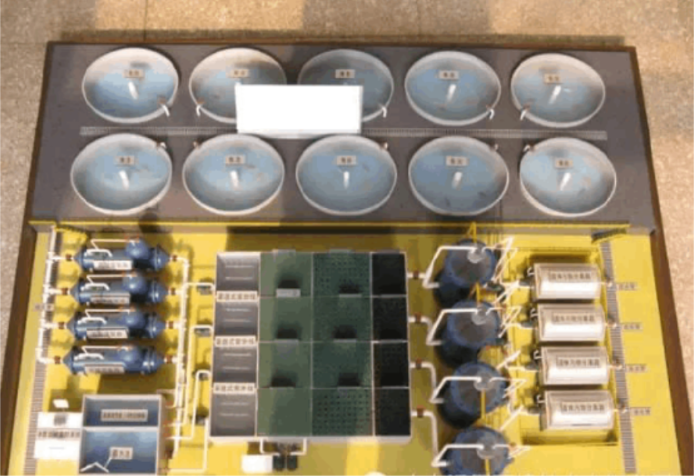

The recirculating aquaculture system is a new type of aquaculture model, which uses a series of water treatment

units to process the wastewater generated in the aquaculture pond and then recycle it. The main principle of

RAS is to integrate advanced technologies in environmental engineering, civil engineering, modern biology,

electronic information and other disciplines to remove residual bait feces, ammonia nitrogen (TAN), nitrite nitrogen

(NO2--N ) and other harmful pollutants. For the purpose of purifying the breeding environment, the process of re-entering the purified water into the breeding pond by using physical filtration, biological filtration, removal of CO2,

disinfection, oxygenation, temperature adjustment and other treatments. It can not only solve the problem of low

utilization rate of water resources, but also provide a stable, reliable, comfortable and high-quality living environment

for breeding organisms, and provide favorable conditions for high-density farming.

Imagine a futuristic fish farm where water is continuously recycled and treated to maintain optimal conditions for growth. This innovative approach, known as Recirculating Aquaculture Systems (RAS), offers a sustainable solution for modern aquaculture. By eliminating the need for wild fish as a food source and reducing environmental impact, RAS becomes a cornerstone of sustainable seafood production.

The Importance of RAS

RAS is more than just a farming system; it's a revolution in aquaculture. It minimizes water pollution, supports disease control, and ensures minimal ecological disruption. For instance, fish species like tilapia thrive in RAS systems with lower salinity, while marine species such as sea bass benefit from the controlled environment of higher salinity.

A Case Study: Hawaiian Success

A recent study highlighted a successful RAS facility in Hawaii, where tilapia were farmed in a closed-loop system. This setup not only reduced water waste but also significantly improved water quality, leading to a 30% increase in fish yield and a 20% reduction in feed costs. This case study underscores the practical benefits of RAS in improving both efficiency and profitability.

Environmental Benefits

RAS systems are crucial for combating climate change. By maintaining stable water temperatures and pH levels, they help prevent algal blooms and fish stress. For example, in colder climates, heat exchangers ensure that fish species like trout, which require moderate temperatures, thrive in their habitats. These systems also reduce the need for large amounts of freshwater, making them ideal for regions with limited water resources.

Design Considerations

A well-designed RAS includes several key components that work together to ensure a healthy and productive environment for fish:

- Fish Tanks: Tailored to the specific needs of the species, these tanks provide a stable environment for growth. For instance, tanks made of concrete or plastic can be engineered to provide a durable and stable habitat.

- Mechanical Filters: Multi-stage filtration ensures water clarity and prevents clogging. For example, a three-stage filter system might include pre-filters, primary filters, and secondary filters to progressively clean the water.

- Biological Filters: Biofilters use bacteria to break down harmful waste products like ammonia and nitrite, converting them into less toxic substances. For example, biofilters can be designed to have a high surface area for microbial growth, enhancing their efficiency.

- Water Treatment Systems: Advanced systems, including UV sterilizers and ion exchange resins, maintain optimal conditions. For example, UV sterilizers can eliminate pathogens, while ion exchange resins can remove heavy metals.

- Pumps: Efficient pumps handle water flow, ensuring continuous operation. For instance, submersible pumps can move water through the system efficiently, while reciprocating pumps can handle larger volumes.

Economic Viability

Investing in energy-efficient pumps and advanced monitoring systems pays off. For example, a study found that RAS systems with energy-efficient pumps saved over 30% on operational costs compared to traditional systems. Regular maintenance and innovative monitoring technologies can further enhance economic feasibility.

Technological Innovations

Regular maintenance is essential for RAS longevity. Scheduled inspections of pumps and filters, along with preventive measures against filter clogging, ensure smooth operation. Backup generators and automated systems provide contingency plans, preventing downtime during outages.

Conclusion

RAS is a game-changer in aquaculture, offering sustainable and efficient solutions for a growing global demand for seafood. By integrating advanced technology, optimizing design, and minimizing environmental impact, RAS systems provide a viable solution for a sustainable future. As technology evolves, the potential for innovation in aquaculture is limitless, offering a pathway to a more sustainable food industry.

In conclusion, the key to successful RAS design lies in a holistic approach that balances environmental, economic, and technological considerations. With careful planning and execution, RAS can provide a sustainable and efficient solution for the future of aquaculture.

Understanding RAS Aquaculture

Definition and Key Characteristics

RAS is a closed system where water is continuously filtered and recycled, creating an enclosed environment for fish farming. This method eliminates the need for large bodies of water and allows farms to be located on land, reducing the impact on coastal environments. RAS systems are characterized by their ability to manage water quality, enhance fish health, and minimize environmental and operational impacts.

Benefits and Challenges

Benefits:

- Flexibility: RAS can be located closer to consumer markets, reducing transportation costs and carbon footprint.

- Sustainability: Closed systems significantly reduce water usage, waste generation, and the risk of disease transmission to wild fish populations.

- Climate Resilience: RAS can operate year-round with controlled environmental conditions, making them less susceptible to climatic variations.

Challenges:

- High Capital Costs: Initial setup and maintenance can be expensive.

- Energy Intensive: Continuous water filtration and recirculation require significant energy consumption.

- Technical Expertise: Requires specialized knowledge and management to ensure optimal system performance.

Regulatory Framework Overview

The regulatory framework for aquaculture is designed to ensure sustainable practices, prevent environmental harm, and protect public health. Both international and national bodies play crucial roles in establishing and enforcing these regulations.

Compliance with Environmental Regulations

Nutrient Management and Waste Control

RAS systems generate minimal waste due to their closed-loop design. Proper nutrient management is crucial. Operators must ensure that waste is properly treated and disposed of to avoid environmental contamination. This includes implementing a controlled water flow system, using efficient filtration processes, and regularly monitoring nutrient levels.

Water Quality Standards and Monitoring

Water quality in RAS systems is continuously monitored to maintain optimal conditions for fish health. Parameters such as dissolved oxygen, pH, temperature, and ammonia levels are regularly checked. Authorities may require operators to submit detailed water quality reports and conduct on-site inspections to ensure compliance.

Biodiversity and Habitat Preservation

Protecting local biodiversity is a key concern. RAS operations must avoid introducing invasive species and minimize impacts on native ecosystems. Operators are often required to undertake environmental impact assessments and implement mitigation measures to preserve local habitats.

Health and Safety Regulations

Disease Prevention and Control

Controlling diseases in RAS systems is critical due to the enclosed environment and high fish density. Operators must adhere to strict biosecurity protocols, including regular health monitoring and isolation practices. The use of pathogens and antibiotics must be strictly regulated to prevent resistance and environmental contamination.

Pathogen and Antibiotic Management

The use of antibiotics and other chemicals in RAS systems is tightly controlled. Operators must maintain detailed records of any medications used and ensure they are applied in a responsible manner to protect both fish and human health.

Worker Safety and Welfare

Ensuring the safety and welfare of workers is paramount. RAS operators must comply with labor laws and provide a safe working environment, including proper training, personal protective equipment, and emergency response protocols.

Inspection and Monitoring Protocols

Regular Inspections by Regulatory Bodies

Regular inspections by regulatory agencies are essential to ensure compliance with all applicable regulations. These inspections cover various aspects of operations, from water quality and waste management to biosecurity and worker welfare.

Data Logging and Record-Keeping

Traceability and Certification Programs

Achieving and maintaining certification through organizations like the Aquaculture Stewardship Council (ASC) can provide an additional layer of assurance. These programs ensure that operations meet stringent environmental and social standards, enhancing market access and consumer confidence.

Successful Implementation of Regulatory Frameworks

Successful RAS Operations

Several RAS operations have successfully implemented rigorous regulatory frameworks. For example, a land-based RAS farm in New Zealand demonstrated compliance by regularly testing water quality, implementing effective biosecurity measures, and maintaining detailed records of all operations. This farm not only met regulatory requirements but also achieved ASC certification, validating its sustainable practices.

Lessons Learned and Best Practices

Key lessons from successful RAS operations include:

- Proactive Monitoring: Regular and meticulous monitoring of environmental and operational parameters.

- Collaboration: Working closely with regulatory bodies and industry experts to stay informed about best practices.

- Continuous Improvement: Regularly reviewing and updating regulatory compliance measures to ensure ongoing sustainability.

Comparative Analysis: RAS vs. Conventional Aquaculture

Regulatory Requirements Comparison

RAS Aquaculture:

- Nutrient Management: Stricter controls on waste and nutrient management.

- Water Quality Monitoring: More frequent and detailed water quality assessments.

- Biosecurity: Higher standards for disease prevention and pathogen control.

Conventional Aquaculture:

- Nutrient Management: Generally less stringent waste management practices.

- Water Quality Monitoring: Less frequent and less detailed water quality assessments.

- Biosecurity: Lower standards for disease prevention.

Pros and Cons of Regulatory Compliance

Pros:

- Environmental Protection: RAS operations that comply with regulations minimize environmental impacts.

- Market Access: Compliance enhances market access and consumer trust.

- Long-Term Viability: Meeting regulatory requirements ensures long-term sustainability and success.

Cons:

- Cost: Initial setup and maintenance costs can be high.

- Complexity: Strict regulations may require additional resources and expertise.

- Technological Dependence: Reliance on advanced technology and specialized management.

Future Trends and Emerging Standards

Emerging Technologies and Practices

Technological advancements in RAS are expected to drive further improvements in efficiency and sustainability. Innovations such as advanced filtration systems, precise environmental control, and real-time data monitoring are likely to become more prevalent.

Future Regulatory Trends and Challenges

As RAS grows in importance, regulatory frameworks will continue to evolve. Future challenges may include:

- Technological Adaptation: Keeping up with the rapid pace of technological advancements.

- Regulatory Consistency: Ensuring consistent and harmonized standards across different regions.

- Public Awareness: Building public trust and understanding of the benefits and challenges of RAS.