Container flexitank export

(1) Flexitank VS. ISO TANK

1. The maximum volume of each flexitank container is 24,000 liters, which is the same as a tank container. However, the shipping cost is calculated based on an ordinary 20-foot international standard container. Compared with the high shipping cost of a tank container, it has obvious advantages.

2. The supply and distribution of tank containers are subject to many conditions, which often affect customers’ normal import and export plans. Coupled with the higher inland ferry container fees and loading and unloading fees, the burden on customers is even heavier. However, flexitanks are not affected by supply, distribution, geography and environment. They have no inland ferry fees, are small in size, are easy to transport, and are convenient, efficient and safe to load and unload.

3. The rental fee of tank containers (about 15 US dollars per day), the return fee and the cleaning fee (about 200 US dollars) also put too much unnecessary financial burden on customers, but there is no need for such expenses with flexitanks. , greatly saving shipping costs for customers.

4. Compared with the tight supply and space of tank containers, the use of flexitanks for transportation eliminates the need to consider the shortage of space and space, which further ensures customers' on-time import and export plans and reduces customer operating costs.

(2) Flexitank VS. 200L iron drum

1. Each 20-foot international standard container can ship up to 80 pieces of 200 liters of iron. Calculated at 150-200 yuan per iron drum, the packaging cost of each container shipment is 12,000-16,000 yuan. Currently, each container The prices of flexitanks are much lower than the total price of 80 iron drums, and only the packaging cost has been significantly reduced.

2. If we also consider that each 20-foot international standard container can be loaded with a maximum of 17,600 liters in an iron drum, but can be loaded with a maximum of 24,000 liters using a container flexitank, the freight required to be paid on the basis of drum packaging remains unchanged, but it can An extra 6,400 liters of goods can be loaded; in other words, the goods that originally required 4 containers can now be shipped in 3 containers, saving the transportation cost and packaging cost of 1 container, and the unit freight cost has been reduced a lot.

3. In addition, flexitanks are easy to operate. Two people can easily complete all loading and unloading work in just one hour, completely eliminating the complicated operating procedures, manpower, working hours, required materials, etc. required for barreled goods. expenditures.

(3) Flexitank VS. 1000L IBC

First of all, the purchase cost of IBC barrels is high. Each IBC barrel can hold about 1.2 tons at most, and each 20-foot international standard container can ship up to 18 IBC barrels. Calculated at RMB 1,200 per IBC barrel, the cost of shipping one container each time The packaging cost is 21,600 yuan, and the current price of each container of flexitank is much lower than the total price of 18 IBC barrels. Only the packaging cost has been significantly reduced.

Secondly, the volume of IBC barrels is limited. When each 20-foot international standard container is shipped in IBC barrels, the maximum volume is 21,600 liters, while the maximum volume of container flexitanks can be loaded to 24,000 liters. The freight that needs to be paid on the basis of IBC barrels remains the same , but it can carry an additional 2,400 liters of goods, and the unit freight cost is greatly reduced.

Thirdly, the loading and unloading of IBC barrels must require forklifts and other equipment, and the loading and unloading process takes a long time, while the loading and unloading of container flexitanks does not require any mechanical equipment. It only takes two people to complete the operation in one hour, which can not only reduce the loading and unloading costs of customers , and can also save customers a lot of time.

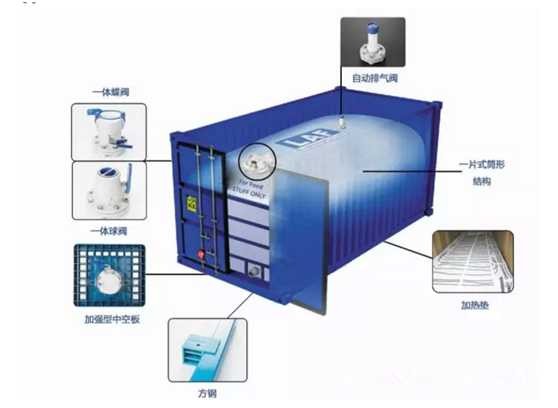

4. Structure of container flexitank.

1. Outer layer: one layer of outer bag: high-strength wear-resistant coated polypropylene (PP) woven fabric

Inner layer: three/four layers Inner bag: food-grade high-strength modified polyethylene (PE) film

Loading and unloading port: 3-inch food-grade butterfly valve, ball valve and safe and stable integrated valve

3. Specifications and models of liquid bag

Description of flexitank model: Take "24KL TLTD Flexitank 4layers LLDPE W/PRV" as an example, the full code interpretation of this model is "24000litres, Top Loading & Top discharge, Flexitank 4 layers of LLDPE, with Pressure Release Valve". That is, "a flexitank with a capacity of 24,000 liters, a top loading and unloading operation method, a 4-layer LLDPE material, and a vent valve."

5. Selection criteria for container flexitank export by sea:

Each set of container flexitank is composed of a container flexitank, square steel (or frame door stop), paper baffle (or PP hollow board), corrugated paper, vertical square steel (or plywood strips, or foam strips).

Containers for flexitanks should be suitable for the safe and legal transportation of non-dangerous liquid goods. Containers must be selected according to the following criteria:

① Containers should be manufactured in strict accordance with international standards. Their design, size, load-bearing, testing, identification, nameplates and operating requirements should all comply with international standards.

② The maximum bearing capacity of 30 tons (30,000 kg or 67,000 pounds) should be indicated on the nameplate of the container.

③ The container shall be a 20-foot standard container with an age of not more than 5 years.

④ The container body should not have any repairs.

⑤ The container should be suitable for road, rail and ocean transportation.

⑥ There is a vertical groove next to the door bolt on both sides of the container.

⑦ There are two fully functional bar locks on the left and right doors of the container.

⑧ Containers should not have marks or labels marked with the word "danger" and should not be loaded with any radioactive or toxic substances that are harmful to the human body.

⑨ There should not be any debris, sharp edges, spikes, loose screws, bumps, welding repair marks, etc. in the container that may cause damage to the flexitank. There should be no contaminants on the surface of the box to prevent cross-contamination from leaking into the cargo or reacting with the flexitank material.

6. Flexitank sea bag products and services

1. Sea bag application industry

Food: soybeans, coffee beans, barley, wheat, corn, cocoa powder, fish meal, flour, milk powder, peanuts, lentils, nuts, peas, rice, salt, seeds, starch, sugar, tea, livestock feed, mixed grain feed, etc.

Chemical industry: PVC powder, ABS resin, PTA, zinc powder, polyethylene particles, polypropylene particles, nylon polymer, polycarbonate particles, aluminum powder, fertilizer, glass beads, polyester particles, soda ash, detergent, china clay , titanium dioxide powder, etc.

2. Introduction to sea bags

Container sea bags are also called dry powder bags, dry material bags, and container liners. Usually placed in 2-foot or 40-foot containers, it is used for bulk solid bulk granules, powders and other products.

It can replace ton bags, small packages within 100 kilograms, etc., which can greatly reduce costs of loading, unloading, packaging, transportation and material management:

-Save 75% of comprehensive logistics costs compared to small packaging methods

-Save 50% of comprehensive logistics costs compared to ton bags

3. Example of container flexitank sea bag

7. Precautions for maritime export of containerized flexitanks:

Container flexitanks can only be exported in the form of door-to-door trailers. In addition, the products covered are mainly general cargo liquids, food liquids, and chemical liquids. Dangerous goods cannot be transported in flexitanks.

At present, our company has built a service network covering more than 100 countries and more than 300 major ports or cities in Southeast Asia, Europe, South America, South Africa, the United States, Canada, Australia, India, South Korea, Japan, and the Middle East.

Container flexitank shipping export packing photos

Tel.: +86 17864390557