Aquaculture one-stop solution provider & liquid storage equipment manufacturer.

Shop Best Recirculating Aquaculture System Price in WOLIZE

recirculating aquaculture system price from Shandong Wolize Biotechnology Co., Ltd. has established a reputation for quality, because appropriate quality management systems conforming to the International Standard ISO 9001 requirements are established and implemented for its production. And the effectiveness of those systems is continually improved. The result is this product meets the strictest quality criteria.

WOLIZE differentiates the company from competitors at home and abroad. We have been evaluated at level A for supplying outstanding products and favorable services. The number of customers keeps rising, boosting more sales volume. The products are widely known in the industry and spread over the Internet within a few days once launched. They are sure to gain more recognition.

At WOLIZE, customers don't need to worry about the transportation of the products like recirculating aquaculture system price. By cooperating with reliable logistics companies, we guarantee the goods arrived safely and effectively.

3D Display Video of Aquaculture System Design

1. Turbidity:

Turbidity is an important indicator to measure the amount of suspended particles in water. It can be detected using a turbidity meter. Generally speaking, the turbidity of water should be significantly reduced after being filtered through a filtering drum machine. For example, in unfiltered recirculating aquaculture water, the turbidity may reach tens or even hundreds of NTU (Nephelometric turbidity units), while after effective filtration, the turbidity should ideally be reduced to below 10 NTU. In some aquaculture scenarios with extremely high requirements for water quality, such as precious ornamental fish farming or fish fry cultivation, the turbidity after filtration may need to be controlled at 1 - 5 NTU.

2. Suspended solids content (TTS):

The content of suspended solids in the water is monitored in real time through online sensors. Before filtering, the aquaculture water is sampled and the content of suspended solids is measured, usually in mg/L. After filtering by a filtering drum, the sample is tested again. An effective filtering drum should be able to remove most of the suspended solids. For example, the suspended solids content of the water body with a content of 100 mg/L before filtering should be reduced to about 10 mg/L after filtering by a filtering drum. The specific reduction degree also depends on the filtering accuracy of the filtering drum and the characteristics of the suspended solids in the water body.

3. Filter inspection

After the filtering drum has been running for a while, turn off the device and check the filter. If a layer of impurities is evenly adsorbed on the surface of the filter and no large particles of impurities penetrate, this indicates that the filtration effect is good. On the contrary, if there are many large particles of impurities that have not been filtered on the filter, or there are obvious holes that allow impurities to pass directly, it means that the filtration effect is not good. For example, during the inspection, it is found that a large amount of feed particles, fish feces and other substances that should be filtered remain on the filter instead of being intercepted outside the filter. This is a normal phenomenon; but if a large amount of impurities similar in size to fish feces are found to pass through the filter into the water outlet, there may be a problem with the filter.

Perform integrity tests on the filter regularly. You can use pressure tests or bubble tests. In a pressure test, a certain pressure of gas or liquid is applied to one side of the filter to see if there is any leakage on the other side. A bubble test is to immerse the filter in water, pass gas from one side, and see if there are any bubbles coming out from the other side. If a leak is found, it means that the filter is damaged, which will affect the filtering effect.

4. Compare the appearance and smell of the inlet and outlet water

Appearance:

Carefully observe the appearance of the incoming and outgoing water. If the incoming water is turbid, has color (such as green due to more algae) or has visible impurities floating on it, the outgoing water should become clear and transparent after being filtered by the filtering drum. For example, if the incoming water looks turbid like muddy water, after being filtered by the filtering drum, the water should become clear and you can clearly see the bottom of the water or the inside of the equipment.

odor:

Some aquaculture water contains a lot of odors caused by the decomposition of organic matter, such as fishy smell, rancid smell, etc. After effective filtration by the filtering drum, the odor should be reduced. This is because the filtering drum removes some of the organic matter that produces odors, such as uneaten feed residues and fish excrement. For example, in a recirculating aquaculture system, the incoming water has a distinct fishy smell. After filtering by the filtering drum, if the smell is significantly reduced, this also indicates that the filtration effect is good to a certain extent.

Process Design

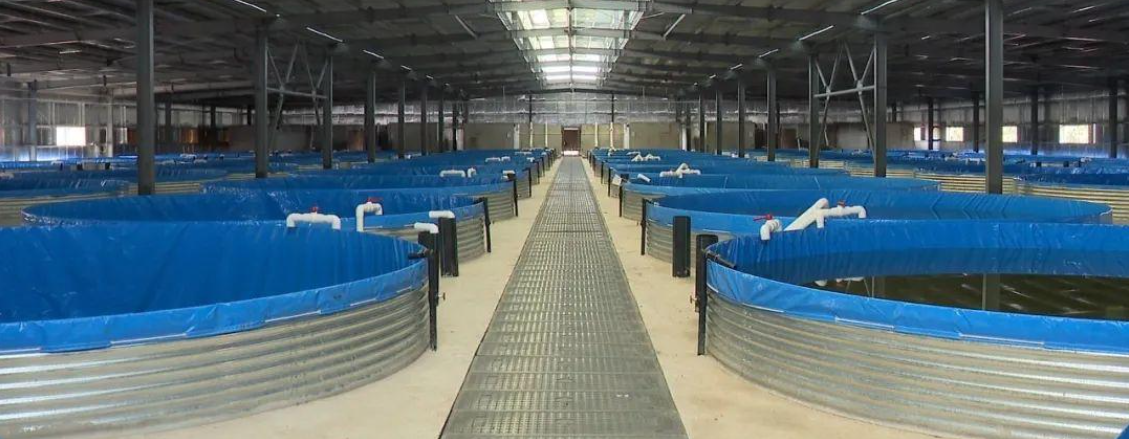

Land-based Industrialized Recirculating Aquaculture System (RAS) (RAS)

Land-based Industrialized Recirculating Aquaculture System (RAS) (RAS) employs modern industrial technologies—including engineering, biotechnology, mechanical equipment, information systems, and scientific management—to comprehensively control the aquaculture process. It creates optimal environmental conditions for aquatic organisms, enabling year-round high-density, high-efficiency, and healthy production, and represents a pivotal direction for the future of aquaculture.

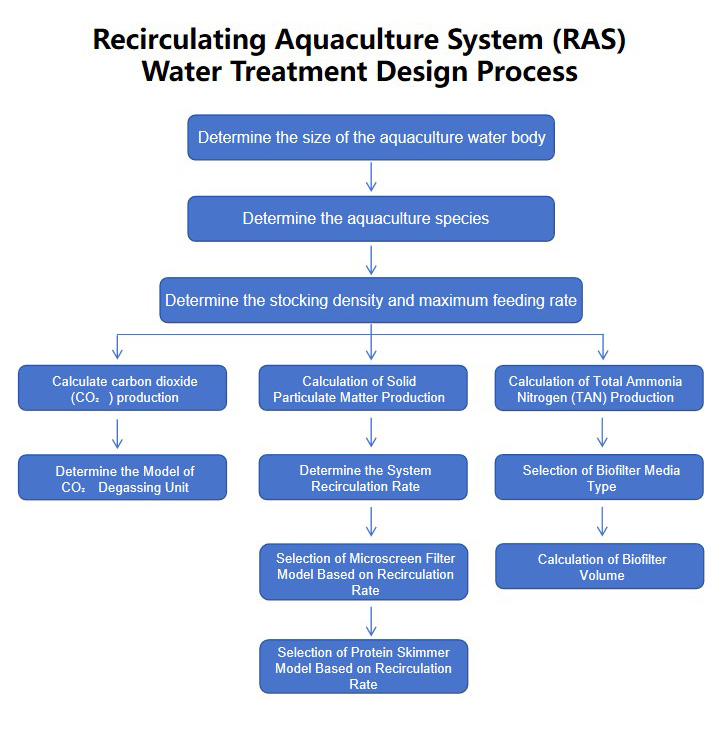

Design Workflow

The design of Recirculating Aquaculture System (RAS) water treatment processes is based on material balance principles, with the core objective of rapidly removing harmful substances (e.g., suspended solids, ammonia nitrogen). Balance equations for these pollutants are established to derive system parameters, which are then refined using engineering practical experience to enhance model reliability.

Key design parameters depend on: Cultured species and Maximum Biomass Carrying Capacity ( Biomass Carrying Capacity=Density×Effective Water Volume ) From this, daily feed input and total waste (solid particles, ammonia nitrogen) are calculated. These values determine equipment specifications (e.g., biofilter size, bio-media volume, microscreen filter capacity).

Step-by-Step Workflow

Step 1: Determine Aquaculture Water Volume

The water volume should be determined based on land availability, financial capacity, and operational scalability.

Step 2: Select Aquaculture Species

Species selection must consider: Water quality compatibility, Farming complexity, Growth cycle, Market demand, Economic viability.

Step 3: Define Stocking Density & Maximum Daily Feed Input

Calculate a reasonable breeding density based on the selected breeding species and the size of the breeding water body, and use this to calculate the maximum daily feeding amount.

Step 4: Quantify Maximum Waste Production

The core of the design of industrialized circulating water treatment process is how to quickly remove the breeding waste generated after feeding. In other words, before feeding, all water indicators in the aquaculture pond are balanced and meet the standards. But after injecting a large amount of feed, the balance of the breeding pond will be disrupted, and a large amount of solid, liquid, and gaseous waste will be generated.

Step 5: Design Water Treatment Equipment

Calculate the performance parameters of water treatment equipment based on the maximum total amount of waste.

Reference Process Parameters

| Reference Process Parameters | |

| Maximum number of cycles for the circulating water system | 24 cycles/day |

Breeding density | Seawater (e.g., Grouper): ≥50 kg/m³ Freshwater (e.g., Bass): ≥50 kg/m³ |

Utilization rate of aquaculture water in the circulating water system | ≥90% |

Water exchange rate | ≤10% |

| UV sterilization rate | ≥99.9% |

Special Operational Modes

In addition to the normal aquaculture mode, the following normal factors should also be considered during the process of Recirculating Aquaculture System (RAS) System (RAS).

1. Power outage emergency mode

Power outages during the aquaculture process can cause fatal losses to the circulating water aquaculture system, so it is necessary to have a power outage emergency mode in the design to prevent power outages from occurring.

1) Install backup generator: Quickly start the generator in case of power outage to ensure the normal operation of the circulating water system.

2) Design overflow pipeline: When the circulating pump is powered off and not working, the overflow pipeline can promptly drain the water in the pump pool to prevent water from overflowing the pump pool.

3) Equipped with emergency oxygenation: farmed animals may die quickly under low dissolved oxygen conditions. The liquid oxygen system does not rely on electricity and can continuously supply oxygen to the breeding pool in the event of a power outage, ensuring the short-term health of the breeding animals.

Disinfection Mode

Relying solely on physical sterilization to disinfect the water is not enough if the breeding animals develop diseases during the breeding process. At this time, some chemicals may be used for disinfection and sterilization. The residue of chemical drugs is likely to enter the biochemical filter through water circulation. The nitrifying bacteria in the biochemical filter are very fragile. The influx of chemicals is likely to kill nitrifying bacteria on a large scale. Therefore, when designing a Recirculating Aquaculture System (RAS) system, there must be a separate disinfection mode. When chemical disinfection is required, ensure that the circulating water does not flow through the biochemical filter.

Idle Mode

In humid environments, metal components of valves (such as valve stems, valve cores, etc.) are prone to chemical reactions with oxygen and moisture in the air, resulting in rust formation. During the breeding process, valves often rotate, and rust is removed by friction between components. However, long-term maintenance will accumulate a large amount of rust between valve components, increase the friction between valve components, and make it difficult for the valve to rotate or even open. In view of this, in the maintenance mode, all valves will be opened once a day to avoid valve failures caused by prolonged disuse.

Given the above special mode, if it is considered that the operation is relatively complex, it will cause unnecessary losses if workers make mistakes. Bang Bang has launched a smart control system for circulating water, which can switch between different operating modes according to different scenarios.

If you want to make a lot of money in aquaculture, you need to pay attention to these items in daily management:

1. Insist on patrolling the pond at least twice a day. The purpose is to check the feeding situation of the fish, the water quality of the pond, and the weather conditions of the day. The feedback from the pond patrol can be used as the basis for feeding and medication in the next few days.

2. Take a sample every 10-15 days, check the growth of the fish, check whether there are any abnormalities on the surface, gills, and internal organs of the fish, if there is any abnormality, find out the cause of the problem in time, and prescribe the right medicine, usually in the early stage of the disease , works best and costs less.

3. For qualified farms, it is necessary to insist on regular water quality testing, at least once every 10 days to test the water quality of all ponds. The testing content includes: PH value, ammonia nitrogen, nitrite, water hardness, pond algae phase, if it is shrimp. Crab, but also to detect Vibrio. If there is an abnormality in the index, the cause must be found out in time and corresponding treatment should be taken.

4. Make a feeding and medication plan every 10-15 days. The feeding plan is calculated based on the amount of sample in the pond, the cumulative amount of feed fed, and the conversion rate to calculate the approximate number of fish in the fish pond, and then arrange according to a certain feeding rate. The medication plan is arranged according to the feedback of daily proofing, and the disinfection is carried out every 2 months. The specific day can be flexibly grasped according to the actual situation.

5. Fish out sick fish and dead fish in time, and remove them frequently to prevent the dead fish from corrupting and polluting water quality.

In addition, in high-density farming operations, the incidence of fish diseases and insect pests is often high, and there are often a large amount of pesticide and other chemical residues in the harvested fish, which will deteriorate the water quality. In the future of aquaculture, natural farming will inevitably be carried out in a low-density farming environment, and the use and pollution of pesticides will be avoided as much as possible.

Aquaculture, the farming of aquatic organisms, has become a cornerstone of global food security. With over 50% of the seafood consumed worldwide being farmed, the demand for sustainable and efficient aquaculture practices is on the rise. Recirculating Aquaculture Systems (RAS) represent a cutting-edge solution, offering reduced water usage, minimized environmental impact, and increased production efficiency. However, before making a significant investment in a RAS for sale, it's crucial to understand the various cost considerations involved in its implementation and operation.

Understanding the Importance of Recirculating Aquaculture Systems

Aquaculture is playing a vital role in meeting the growing demand for seafood. The industry is not only crucial for food security but also for economic development in many regions. Recirculating Aquaculture Systems (RAS) are at the forefront of sustainable aquaculture, offering a range of benefits such as:

- Reduced Water Usage: Unlike traditional farming methods, RAS can use water more efficiently, reducing the overall water footprint.

- Minimized Environmental Impact: RAS helps in reducing waste discharge and the release of chemicals into the environment, making it a more environmentally friendly option.

- Increased Production Efficiency: RAS allows for more precise control over environmental conditions, leading to higher production rates and better crop health.

Initial Investment Costs: Gear and Infrastructure

The initial setup of a RAS is a robust financial undertaking, involving several key components:

- Tanks and Structures: The design and construction of tanks are crucial for system integrity and longevity. For example, a 10,000-gallon tank made of stainless steel can cost around $15,000 to $25,000, depending on the size, material, and complexity.

- Filtration Systems: These systems are essential for maintaining water quality. Advanced filtration technologies like biofilters and mechanical filters can cost between $5,000 and $10,000 for a medium-sized system.

- Offtake Pipes and Components: Proper installation of pipes and associated components ensures efficient water circulation and distribution. A set of high-quality offtake pipes and components can cost around $2,000 to $4,000.

- Energy Requirements: RAS operations are energy-intensive, requiring pumps, heaters, and aeration systems. A typical 100 horsepower pump might consume about 2,000 to 3,000 kWh per month, depending on usage.

- Automation and Control Systems: Sophisticated automation and control systems are necessary for monitoring and regulating water parameters, feeding schedules, and system performance. A basic automation system can cost around $5,000 to $10,000.

Operating Costs: Running an Efficient RAS

Operating an RAS involves ongoing costs, including:

- Electricity Usage: Regular monitoring and optimization of energy consumption can help reduce electricity bills. Using energy-efficient equipment and considering renewable energy sources like solar panels can save about 15-20% on electricity costs.

- Water Treatment Costs: Ongoing chemical and biological treatments are necessary to maintain water quality. A small RAS system might spend around $200 to $400 per month on water treatment chemicals.

- Staffing and Labor Costs: Continuous operation and maintenance of RAS require skilled personnel. This includes labor for cleaning tanks, maintaining equipment, and troubleshooting issues. A medium-sized RAS farm might spend about $5,000 to $10,000 per year on labor costs.

Maintenance and Repairs: Ensuring Longevity

Regular maintenance is crucial for the longevity of RAS components and systems:

- Regular Maintenance: Periodic inspection and servicing of all components ensure the RAS operates efficiently and without failure. For example, a typical maintenance schedule includes quarterly checks and an annual overhaul, costing around $1,000 to $2,000 per year.

- Cost of Replacements and Upgrades: Over time, some components may need to be replaced. Replacing a faulty pump every three years could cost about $2,000 to $3,000. Upgrading older systems to newer, more efficient models can also be a cost consideration, with a high-end upgrade costing around $10,000 to $15,000.

- Spare Parts and Downtime: Temporary downtime due to equipment failures can lead to lost production. Maintaining a stock of spare parts can help minimize disruptions, but this adds to operational costs. A farm might spend about $1,000 to $2,000 on spare parts annually.

Technical and Regulatory Requirements

Compliance with local and international aquaculture regulations is essential:

- Legal and Compliance Costs: The cost of obtaining necessary permits and licenses, as well as the ongoing compliance with environmental regulations, can add to the total cost of operating a RAS. For example, a small farm might spend about $5,000 to $10,000 annually on compliance costs.

- Potential Fines and Penalties: Failure to comply with regulations can result in significant fines and penalties. Ensuring strict adherence to all legal requirements is critical to avoid these expenses. A farm that ignores regulations could face penalties of up to $50,000 in some regions.

Energy Efficiency and Cost Savings

Implementing energy-efficient systems can significantly reduce operational costs:

- Comparison with Traditional Methods: RAS often use less water and fewer resources than traditional farming methods, leading to long-term cost savings. Advanced technologies that reduce energy consumption are particularly beneficial. For instance, an RAS might save about 30-40% on electricity costs compared to a conventional farm.

- Water Usage Optimization: Efficient water management can further reduce costs by minimizing waste. Modern RAS systems are designed to optimize water usage, leading to lower operational expenses. A well-managed RAS can save about 50-60% of water compared to traditional methods.

Economic Viability and Return on Investment

Evaluating the economic viability of a RAS involves a detailed cost-benefit analysis:

- Cost-Benefit Ratios: Analyzing the ratio of initial and ongoing costs against the financial returns of selling the products can help determine the financial feasibility of the RAS. Factors such as market demand, pricing, and production capacity are critical. For example, a medium-sized RAS farm might see a ROI of about 20-30% within five years.

- Examining case studies of successful RAS implementations can provide valuable insights into the financial performance of similar systems. These studies often highlight the profitability and efficiency of RAS. One successful farm reported a 40% increase in production and a 35% reduction in operating costs over two years.

- Market Demand and Pricing: Understanding market demand and pricing trends can influence the return on investment. High-demand species and competitive pricing can enhance the profitability of RAS. For instance, a farm focusing on tilapia might see a 25-30% higher profit margin compared to traditional farming methods.

Balancing Costs and Benefits

Balancing costs and benefits is the key to a successful investment in a recirculating aquaculture system. By carefully considering initial investment, operating costs, maintenance, regulatory compliance, and long-term efficiency, potential RAS buyers can make informed decisions. Future trends in RAS technology, such as increased automation and sustainable practices, are likely to further reduce costs and enhance profitability. Emphasizing these considerations will ensure that RAS remains a viable and sustainable solution for future aquaculture endeavors.

By understanding and managing the various cost considerations, aquaculturists can ensure the success and sustainability of their operations. The upfront investment in RAS might seem daunting, but the long-term benefits of efficiency, sustainability, and profitability make it a worthwhile investment.