Aquaculture one-stop solution provider & liquid storage equipment manufacturer.

Ras Aquaculture: Things You May Want to Know

ras aquaculture is important for Shandong Wolize Biotechnology Co., Ltd. to expand the market. The adoption of constantly improved production techniques and the implementation of strict quality control system during the production ensure the stable quality and relatively low defective rate of the product. Besides, with the advantages of strong functionality, high performance, and low cost, the product is highly cost-effective.

WOLIZE now has been one of the hottest brands in the market. The products are proved to bring benefits for their long-lasting performance and favorable price, so they are most welcome by customers now. The word-of-mouth comments with regard to the design, function, and quality of our products are spreading. Thanks to that, our brand fame has been greatly widespread.

With regard to our after-sale service, we are proud of what we have been doing for these years. At WOLIZE, we have a full package of service for products like the above-mentioned ras aquaculture. Custom service is also included.

Daily maintenance of filtering drum machine

Daily maintenance of the circulating aquaculture filtering drum machine is essential for its normal operation and extended service life. The following are some common maintenance methods:

1. Filter cleaning:

The filter is the core component of the filtering drum and is easily clogged by impurities in the water. Clean the filter regularly (such as daily or weekly) according to the degree of pollution in the aquaculture water and the frequency of use of the filtering drum. For some aquaculture environments with poor water quality and more impurities, it may be necessary to clean it once a day. Avoid using sharp tools when cleaning to avoid damaging the filter.

2. Check the equipment operation status

1) Motor inspection:

Check the motor's operation regularly, including the motor's temperature, sound, and vibration. The temperature of a normally operating motor should be within a reasonable range and generally will not overheat. If the motor housing feels hot to the touch, it may be that the motor is overloaded or has poor heat dissipation.

Listen to the sound of the motor running to see if it is normal. Under normal circumstances, the motor running sound is stable, without abnormal noise or friction. If there is a harsh sound or periodic impact sound, it may mean that the internal parts of the motor are worn or foreign objects have entered.

Observe the vibration of the motor. Excessive vibration may be caused by unbalanced motor installation, impeller damage, etc. A vibration meter can be used (if conditions permit) for accurate measurement. Generally, the vibration amplitude of the motor is required to be within the range specified by the equipment.

2) Water pump inspection:

Check the inlet and outlet water pressure of the water pump. You can observe the pressure change by installing a pressure gauge on the inlet and outlet pipes. Under normal circumstances, the inlet pressure should be stable and the outlet pressure should be within the normal working pressure range of the filtering drum. If the inlet pressure is too low, the inlet pipe may be blocked; if the outlet pressure is too high or too low, the pump impeller may be damaged or air may have entered the pump.

Check the seal of the water pump to prevent water leakage. Check the seal of the water pump regularly to see if there are any water drops seeping out. Minor leaks can be solved by tightening the seal; if the leak is serious, the seal may need to be replaced.

3. Backwash system maintenance

If the filtering drum is equipped with an automatic back washing system, check the operation of the back washing device regularly. Check whether the back washing valve can be opened and closed normally, and whether the back washing time interval and flushing intensity meet the requirements. The back washing parameters can be reasonably adjusted according to the actual situation of the aquaculture water body. For example, when it is found that the filter screen is blocked faster, the back washing time interval can be appropriately shortened or the flushing intensity can be increased. Check whether the back washing water source is clean and avoid using dirty water for back washing, otherwise the filter screen will be contaminated again.

4. Lubrication and tightening

1) Lubrication parts maintenance:

For parts such as bearings and gears on the filtering drum that need lubrication, add lubricating oil or grease regularly (such as once a quarter) according to the requirements of the equipment manual. Choose a suitable lubricant to ensure that it can maintain good lubrication performance in a humid breeding environment.

Before adding lubricant, clean the dirt and old lubricant on the surface of the parts, and then evenly apply or inject new lubricant. Be careful not to use too much lubricant to avoid overflow and contamination of equipment and water.

2) Fastening parts inspection:

Regularly check the bolts, nuts and other fastening parts on the filtering drum machine to prevent loosening due to equipment vibration. Use appropriate tools (such as wrenches) to check and tighten each part one by one, especially the connecting bolts of the inlet and outlet pipes, the mounting bolts of the motor and other key parts.

5. Water quality monitoring and adjustment

Monitor the water quality after being treated by the filtering drum machine regularly (such as once a week). The main monitoring indicators include turbidity, suspended matter content, dissolved oxygen, etc.

Based on the water quality monitoring results, determine whether the filtering effect of the filtering drum is normal. If it is found that the water quality indicators do not meet the aquaculture requirements, such as increased turbidity, the filtering drum may be faulty or the filtering parameters need to be adjusted. At this time, you can check whether the filter is damaged, whether it has been cleaned thoroughly, or whether the filter needs to be replaced.

At the same time, according to the water quality, the operation time and filtration speed of the filtering drum can be reasonably adjusted. For example, in the period of serious water pollution, the operation time of the filtering drum can be appropriately extended and the filtration speed can be increased to ensure good water quality.

The World's Most Advanced Aquaculture System Improvement Model Has Arrived!

Introduction:

For those who love fish and seafood, there's good news! The world's most aquaculture advanced improvement model has finally arrived. This innovation designed to improve your aquaculture experience in every real way imaginable. You wolize create an advanced and safe aquaculture system truly meets your needs whether you are an expert or new to the world of fish and seafood farming, this improvement model will help.

Advantages:

Using the world's aquaculture most advanced has a myriad of benefits. These aquaculture industry systems are designed to help you achieve results are optimal your fish and seafood farm. This aquaculture model helps you produce more seafood with fewer inputs. Plus, it more environmentally friendly than traditional aquaculture systems. By using this operational system, you can also save water, minimize waste and maximize your yield of fish and seafood products. With the quality improved of and seafood products, you'll be able to increase your sales and reap the benefits of your hard work.

Innovation:

The world's most aquaculture advanced model innovative in many ways. It uses technologies are cutting-edge have been tested and developed by experts in the field. This system built with advanced sensors and software allows you to manage your seafood and fish farm even if you're far away. It has a interface user-friendly lets you monitor fish growth and feeding habits from anywhere. It is also offers data are real-time helps you make better decisions which are timely and aquaculture solution sometimes spontaneous.

Safety:

Safety of paramount importance when it comes to aquaculture systems. This why the world's aquaculture most advanced comes with many safety features. It has an water system advanced ensures the purity of the water in which your fish and seafood grow. It also has a built-in emergency response system such as alarms and water level monitoring automatic. In case of an emergency, you'll be notified immediately, giving you time to take any action necessary.

Use:

Using the world's aquaculture most advanced very easy. First, you need to set the operational system according up to the instructions come with it. Once set up, the system operational ready to use. It allows you to automate many of the systems are operational processes involved in fish and seafood farming. This makes it easy for those with busy lives to manage their farms without it interfering too much with their activities are daily

How to Use:

To get the most out of the world's most aquaculture advanced, you need to set up the appropriate conditions for your fish and seafood. The system comes with easy-to-use controls let you adjust things like water oxygen and temperature levels. You can also monitor the water level, pH levels, and nutrient levels using the sensors are advanced. By monitoring all these conditions, you can ensure your fish and seafood are getting the environment ideal giving you the best possible results.

Service:

The world's aquaculture most advanced comes with excellent customer support. The aquaculture system company provides you with extensive training material, and they offer 24/7 support via email or phone. You out if you have any presssing issues or queries, their team of experts will be happy to help.

Quality:

One of the biggest benefits of using the world's aquaculture most advanced the quality of the fish and seafood products it produces. The system designed to help you produce healthy and fish high-quality seafood. It is healthy for both you and your clients when you use this system, you'll be able to produce fish and seafood free from harmful substances, making. Due to the high-quality standards of fish and seafood produced, you'll be able to sell your products at a higher price, resulting in increased profitability.

Application:

The world's aquaculture most advanced has revolutionized the fish and seafood farming industry. It is a solution innovative helps you maximize your productivity while also ensuring the safety of your product. This system ideal for people who are new to the world of fish and seafood farming, as well as experts who want to take their farm to the level next. It is also ideal for those who want to produce healthy and fish seafood high-quality are both eco-friendly and sustainable.

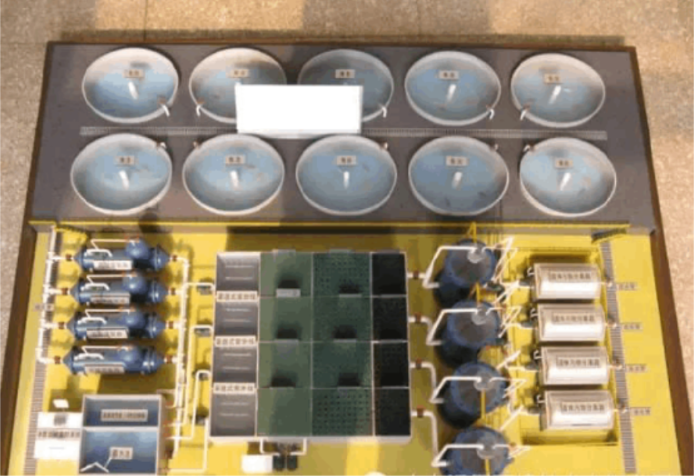

The recirculating aquaculture system is a new type of aquaculture model, which uses a series of water treatment

units to process the wastewater generated in the aquaculture pond and then recycle it. The main principle of

RAS is to integrate advanced technologies in environmental engineering, civil engineering, modern biology,

electronic information and other disciplines to remove residual bait feces, ammonia nitrogen (TAN), nitrite nitrogen

(NO2--N ) and other harmful pollutants. For the purpose of purifying the breeding environment, the process of re-entering the purified water into the breeding pond by using physical filtration, biological filtration, removal of CO2,

disinfection, oxygenation, temperature adjustment and other treatments. It can not only solve the problem of low

utilization rate of water resources, but also provide a stable, reliable, comfortable and high-quality living environment

for breeding organisms, and provide favorable conditions for high-density farming.

Aquaculture, the farming of aquatic organisms in controlled environments, is vital for global food security. However, traditional aquaculture systems face significant challenges such as water pollution, disease spread, and space constraints. These issues have driven the development of innovative solutions like recirculating aquaculture systems (RAS).

What Are Recirculating Aquaculture Systems (RAS)?

Recirculating aquaculture systems are closed-loop systems that constantly clean and reuse the water, drastically cutting the need for fresh water. The key components include mechanical and biological filters, aerators, and water quality monitors. These components help maintain optimal water quality and create a controlled environment for fish and other aquatic organisms.

Types of Aquaculture Systems Compared to RAS

Open Water Systems vs. RAS: Traditional open water systems, like ponds, rely on large quantities of water and are vulnerable to pollution and disease. RAS are more contained, offering better control over water quality and environmental factors.

Pond Aquaculture vs. RAS: Pond aquaculture is common and cost-effective but can lead to environmental degradation and water scarcity. RAS can be more intensive, producing higher yields with minimal environmental impact.

Flow-Through Systems vs. RAS: Flow-through systems discharge water after use, making them less efficient in terms of water and feed usage. RAS, by reusing water, are more efficient and sustainable.

Recirculating Aquaponics vs. RAS: Aquaponics integrates aquaculture with hydroponics, but RAS are more focused on fish production. Recirculating aquaponics is more complex but offers a more integrated approach to food production.

Broodstock Husbandry in Traditional Systems vs. RAS: Traditional breeding systems often use natural conditions, which can be difficult to replicate. RAS provide a highly controlled environment for breeding and growing offspring.

Advantages of Recirculating Aquaculture Systems

Efficiency in Water Usage and Feed Utilization:

RAS can reuse up to 90% of the water, drastically reducing the need for freshwater resources. This efficiency lowers operational costs and minimizes environmental impact.Enhanced Disease Control:

The controlled environment of RAS makes it easier to monitor and control diseases, leading to healthier fish populations.Improved Water Quality Management:

RAS can maintain optimal water quality by continuously filtering and treating the water, reducing the need for chemicals.Potential for Year-Round Production:

RAS can operate year-round, regardless of weather conditions, leading to consistent production and reduced seasonality.Reduced Environmental Footprint:

By reusing water and minimizing waste, RAS significantly reduce the environmental impact of aquaculture.

Challenges in Implementing RAS

High Initial Capital Investment:

Setting up a RAS can be expensive, requiring significant investment in infrastructure and equipment.Complex Maintenance and Technical Expertise Required:

RAS need regular maintenance and monitoring to operate efficiently, requiring specialized knowledge and expertise.Energy Requirements and Sustainability:

Running a RAS consumes energy for filtration, water circulation, and aeration, which can be challenging in regions with limited access to reliable electricity.Biological and Chemical Filtration Challenges:

Ensuring proper filtration and maintaining a stable environment can be complex and require ongoing adjustments.

Successful Implementation of RAS

Urban Fish Farms Using RAS:

Urban RAS systems have succeeded in cities like Singapore, providing a localized and sustainable source of fresh fish in urban areas.Coastal Fish Farms Transitioning from Open Water to RAS:

Coastal farms in Norway have transitioned to RAS with the help of government grants and subsidies, improving water quality and disease control.Indoor RAS Systems in Controlled Environments:

Indoor RAS systems in climate-controlled environments have demonstrated higher productivity and better control over environmental factors, leading to higher fish yields.

Future Prospects of Recirculating Aquaculture Systems

Market Trends and Growth Potential:

The market for RAS is growing rapidly, driven by concerns about water scarcity and the need for sustainable food production.Technological Advancements and Innovations:

Ongoing technological developments are making RAS more efficient and user-friendly, reducing barriers to new farmers.Policy and Regulatory Support for RAS:

Governments and organizations are increasing support for RAS through policies and funding, promoting its adoption.Integration of RAS with Sustainable Practices:

Combining RAS with other sustainable practices, like aquaponics and organic agriculture, can create holistic and environmentally friendly systems.

Conclusion

Recirculating aquaculture systems offer a promising solution to the challenges of traditional aquaculture. By providing a controlled and sustainable environment, RAS can enhance productivity, reduce environmental impact, and ensure the long-term viability of aquaculture. While implementation has challenges, the benefits of RAS make it an attractive option for both small and large-scale aquaculture operations.

We encourage the aquaculture community to embrace RAS technologies and drive innovation in sustainable aquaculture practices. Together, we can ensure a more sustainable and secure future for aquaculture production.

Aquaculture has come a long way since its ancient origins. Today, it is a vital industry that contributes significantly to global food security. Traditional methods like pond and net-pen systems, while effective, have limitations. Enter the recirculating aquaculture system (RAS), a game-changer that offers a dynamic solution to these challenges.

A recirculating aquaculture system (RAS) is a closed-loop system where water is continuously filtered and re-circulated back into fish tanks. This system is like a mini-ecosphere designed to keep fish healthy and thriving. In a RAS, water is constantly cleaned and reused, creating a controlled environment that mimics nature. Think of it as a self-contained aquatic paradise!

- Fish Tanks: These are where the fish live and grow.

- Mechanical Filters: Remove solid waste, such as fecal matter, which can deteriorate water quality.

- Biological Filters: Convert toxic waste products like ammonia into non-toxic substances through bacterial processes.

- Pumps and Pipes: Move water through the system, ensuring constant circulation.

- Oxygenation Devices: Ensure fish have enough oxygen, a critical component for their health and growth.

- Disinfection Systems: Remove pathogens and diseases, keeping fish healthy.

Key Components and Configuration of a RAS

Understanding these components is crucial for the success of a RAS. Heres a quick rundown:

- Fish Tanks: Vital for housing the fish and maintaining steady water conditions.

- Mechanical Filters: These catch solid waste, keeping the water clean.

- Biological Filters: These are like the kidneys of the RAS, converting harmful toxins into harmless substances.

- Pumps and Pipes: These keep the water circulating, ensuring it remains fresh.

- Oxygenation Devices: These give the fish what they need to breathe, much like the air we need.

- Disinfection Systems: These ensure the fish stay healthy by getting rid of harmful bacteria and pathogens.

Defining an Optimal Recirculating Aquaculture System

Achieving an optimal RAS involves meeting specific criteria that ensure high performance and sustainability. Heres what makes an RAS truly optimal:

- Efficiency in Resource Utilization: An optimal RAS should maximize the use of water, energy, and feed while minimizing waste.

- Consistent Water Quality: Maintaining consistent water quality is crucial for fish health. This includes levels of dissolved oxygen, pH, and temperature.

- Cost-Effectiveness: Minimizing operational and maintenance costs while achieving high production yields.

- Sustainability: Ensuring minimal environmental impact and responsible waste management.

Key Performance Indicators (Performance Metrics)

To measure the success of an optimal RAS, we use key performance indicators:

- Water Reuse Efficiency: The percentage of water that can be recycled.

- Energy Consumption: The amount of energy required to run the system.

- Feed Conversion Rate: How efficiently fish convert food into growth.

- Disease Incidence: How often and how severe disease outbreaks are.

- Fish Health Metrics: Growth rate, mortality, and overall health of the fish.

Benefits of an Optimal Recirculating Aquaculture System

An optimal RAS significantly reduces environmental impact and enhances efficiency in resource utilization, leading to cost-effectiveness and economic benefits.

Environmental Impact Reduction

- Water Conservation: By recycling up to 90% of the water, it conserves a vital resource.

- Waste Management: Removes solid and liquid waste, which can be treated and reused.

- Reduced Pollution: Minimizes the release of pollutants into the environment.

Efficiency Enhancement in Resource Utilization

- Optimized Water Use: High water reuse reduces the need for fresh water.

- Energy Efficiency: Advanced filtration and water circulation systems use energy efficiently.

- Feed Efficiency: Enhanced feed conversion rates lead to better growth and less waste.

Cost-Effectiveness and Economic Benefits

- Lower Operational Costs: Reduced need for water, energy, and feed.

- Increased Production: Higher fish yields and faster growth rates.

- Market Access: Better control over product quality and consistency, leading to higher market value.

Real-World Applications of Optimal RAS

A notable example of an optimal RAS in commercial aquaculture is a Tilapia farm in California. This farm achieved outstanding results by:

- Using Advanced Filtration: Implementing state-of-the-art biological and mechanical filters to maintain water quality.

- Energy Efficiency: Utilizing energy-efficient pumps and solar power to reduce energy consumption.

- Fish Health Monitoring: Regularly monitoring fish health and water parameters to prevent disease outbreaks.

Compared to traditional methods, an optimal RAS offers clear advantages:

- Water Conservation: Requires significantly less water.

- Disease Prevention: Reduces the risk of disease spread.

- Environmental Impact: Minimizes pollution and waste.

Potential for Scalability and Adaptability

The scalability and adaptability of optimal RAS make it suitable for various applications, from small-scale operations to large commercial farms. This flexibility allows for tailored solutions to meet specific needs and market demands.

Technological Advancements in RAS Optimization

Recent technological advancements have further optimized RAS systems:

- Advanced Sensors and Monitoring Systems: Real-time data collection and analysis for better system management.

- Automation and AI: Automated control systems and AI for predictive maintenance and optimization.

Integration of Advanced Sensors and Monitoring Systems

These technologies enable real-time monitoring of critical parameters such as water quality, temperature, pH, and dissolved oxygen levels. This allows for immediate adjustments to maintain optimal conditions for fish.

Automation and AI Applications in RAS

Automation and AI applications enhance RAS operations by:

- Predictive Maintenance: Identifying potential issues before they become critical.

- Efficient Feeding: Automated feed delivery based on fish requirements.

- Disease Detection: Early detection of diseases through machine learning algorithms.

Challenges and Considerations for Implementing Optimal RAS

Implementing an optimal RAS requires significant initial investment in equipment and infrastructure. However, the long-term benefits make this investment worthwhile. Technical expertise is crucial for the operation and maintenance of RAS systems, and regular maintenance is essential to ensure optimal performance. Regulatory compliance and environmental standards must also be adhered to ensure sustainable operations.

Future Prospects and Trends in RAS

The global RAS market is expected to grow significantly due to increased demand for sustainable seafood and stringent environmental regulations. Emerging trends include:

- Vertical Farming: Integrating RAS with vertical farming techniques.

- Aquaponics: Combining RAS with plant cultivation for integrated food production.

- Biogas Production: Utilizing organic waste to generate biogas for energy.

RAS plays a crucial role in sustainable seafood production by providing a controlled environment that minimizes environmental impact and ensures high-quality fish.