Aquaculture one-stop solution provider & liquid storage equipment manufacturer.

Aquaculture Tanks in-depth Demand Report

aquaculture tanks, with its efficiency and innovation, has become a new favorite of people. It undergoes a strict testing process before its final launch so it ensures faultless quality and stable performance. Also, with the strong product quality as the foundation, it takes new markets by storm and succeeds in attracting entirely new prospects and customers for Shandong Wolize Biotechnology Co., Ltd..

WOLIZE's popularity has been increasing rapidly. Equipped with innovative technology and advanced facilities, we make the product be of fantastic durability and enjoys a very long service period. Many customers send e-mails or messages to express their thanks because they have gained much more benefits than before. Our customer base is gradually becoming greater and some customers travel across the world to pay a visit and cooperate with us.

With years of experience in providing customization service, we have been acknowledged by customers at home and aboard. We have signed a long-term contract with the renowned logistic suppliers, ensuring our freight service at WOLIZE is consistent and stable to improve customer satisfaction. Besides, the long-term cooperation can greatly reduct freight cost.

Process Design

Land-based Industrialized Recirculating Aquaculture System (RAS) (RAS)

Land-based Industrialized Recirculating Aquaculture System (RAS) (RAS) employs modern industrial technologies—including engineering, biotechnology, mechanical equipment, information systems, and scientific management—to comprehensively control the aquaculture process. It creates optimal environmental conditions for aquatic organisms, enabling year-round high-density, high-efficiency, and healthy production, and represents a pivotal direction for the future of aquaculture.

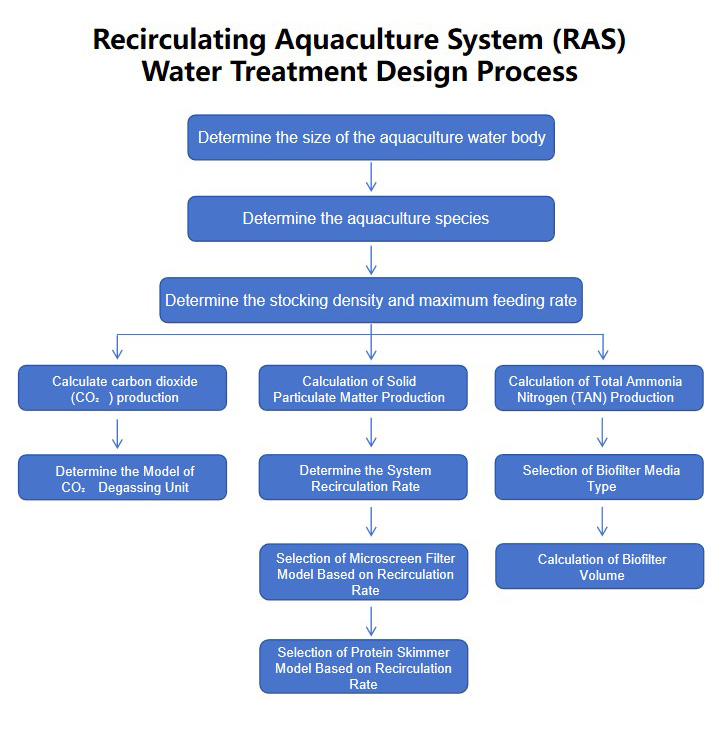

Design Workflow

The design of Recirculating Aquaculture System (RAS) water treatment processes is based on material balance principles, with the core objective of rapidly removing harmful substances (e.g., suspended solids, ammonia nitrogen). Balance equations for these pollutants are established to derive system parameters, which are then refined using engineering practical experience to enhance model reliability.

Key design parameters depend on: Cultured species and Maximum Biomass Carrying Capacity ( Biomass Carrying Capacity=Density×Effective Water Volume ) From this, daily feed input and total waste (solid particles, ammonia nitrogen) are calculated. These values determine equipment specifications (e.g., biofilter size, bio-media volume, microscreen filter capacity).

Step-by-Step Workflow

Step 1: Determine Aquaculture Water Volume

The water volume should be determined based on land availability, financial capacity, and operational scalability.

Step 2: Select Aquaculture Species

Species selection must consider: Water quality compatibility, Farming complexity, Growth cycle, Market demand, Economic viability.

Step 3: Define Stocking Density & Maximum Daily Feed Input

Calculate a reasonable breeding density based on the selected breeding species and the size of the breeding water body, and use this to calculate the maximum daily feeding amount.

Step 4: Quantify Maximum Waste Production

The core of the design of industrialized circulating water treatment process is how to quickly remove the breeding waste generated after feeding. In other words, before feeding, all water indicators in the aquaculture pond are balanced and meet the standards. But after injecting a large amount of feed, the balance of the breeding pond will be disrupted, and a large amount of solid, liquid, and gaseous waste will be generated.

Step 5: Design Water Treatment Equipment

Calculate the performance parameters of water treatment equipment based on the maximum total amount of waste.

Reference Process Parameters

| Reference Process Parameters | |

| Maximum number of cycles for the circulating water system | 24 cycles/day |

Breeding density | Seawater (e.g., Grouper): ≥50 kg/m³ Freshwater (e.g., Bass): ≥50 kg/m³ |

Utilization rate of aquaculture water in the circulating water system | ≥90% |

Water exchange rate | ≤10% |

| UV sterilization rate | ≥99.9% |

Special Operational Modes

In addition to the normal aquaculture mode, the following normal factors should also be considered during the process of Recirculating Aquaculture System (RAS) System (RAS).

1. Power outage emergency mode

Power outages during the aquaculture process can cause fatal losses to the circulating water aquaculture system, so it is necessary to have a power outage emergency mode in the design to prevent power outages from occurring.

1) Install backup generator: Quickly start the generator in case of power outage to ensure the normal operation of the circulating water system.

2) Design overflow pipeline: When the circulating pump is powered off and not working, the overflow pipeline can promptly drain the water in the pump pool to prevent water from overflowing the pump pool.

3) Equipped with emergency oxygenation: farmed animals may die quickly under low dissolved oxygen conditions. The liquid oxygen system does not rely on electricity and can continuously supply oxygen to the breeding pool in the event of a power outage, ensuring the short-term health of the breeding animals.

Disinfection Mode

Relying solely on physical sterilization to disinfect the water is not enough if the breeding animals develop diseases during the breeding process. At this time, some chemicals may be used for disinfection and sterilization. The residue of chemical drugs is likely to enter the biochemical filter through water circulation. The nitrifying bacteria in the biochemical filter are very fragile. The influx of chemicals is likely to kill nitrifying bacteria on a large scale. Therefore, when designing a Recirculating Aquaculture System (RAS) system, there must be a separate disinfection mode. When chemical disinfection is required, ensure that the circulating water does not flow through the biochemical filter.

Idle Mode

In humid environments, metal components of valves (such as valve stems, valve cores, etc.) are prone to chemical reactions with oxygen and moisture in the air, resulting in rust formation. During the breeding process, valves often rotate, and rust is removed by friction between components. However, long-term maintenance will accumulate a large amount of rust between valve components, increase the friction between valve components, and make it difficult for the valve to rotate or even open. In view of this, in the maintenance mode, all valves will be opened once a day to avoid valve failures caused by prolonged disuse.

Given the above special mode, if it is considered that the operation is relatively complex, it will cause unnecessary losses if workers make mistakes. Bang Bang has launched a smart control system for circulating water, which can switch between different operating modes according to different scenarios.

About WOLIZE

About WOLIZE

Our Aquaculture System: A Perfect Balance of Environment and Technology

As humans, it is our responsibility to take care of our planet and ensure our actions do not have a impact negative the environment. same we also want to maximize our resources and use technology to our advantage at the time. At our wolize company, we have found a solution to this problem nagging our aquaculture system. Here are some of the advantages, innovations, and applications of our system, as well as instructions on how to use it and information about our quality and service.

Advantages of Our System

Our aquaculture system has advantages are several including being efficient and eco-friendly. It has been designed by us to conserve water and reduce waste. This means we use less water and produce less waste than traditional aquaculture methods, which good for both the environment and our business.

Another advantage our system designed for easy use. You don't need to be an expert to use it, and it is customizable to fit your needs. With this operational system, you can grow fish, shrimp, and other creatures are aquatic and efficiently.

Innovations in Our System

We have incorporated the latest technologies into our aquaculture system to make it the most innovative in the market. One of the most innovations are important the use of artificial intelligence to monitor and maintain the system. The aquaculture industry system can detect any problems or changes in the water quality and take action corrective intervention human.

The system also includes automated feeding, which means the fish and shrimp are fed at the time right in the right amount to eliminate waste and improve efficiency. Finally, our system includes a biofilter removes waste from the water and ensures the water quality remains optimal for the creatures are aquatic grow.

Safety of Our System

We take the safety of our customers seriously, which why our system designed to be safe and easy to use. The aquaculture solution materials we use to build the operational system are high quality and safe, and we follow strict safety standards in our manufacturing process.

In addition, we offer training to our customers to ensure they know how to use the system operational. We also provide ongoing support and maintenance to ensure the operational system functioning properly and safely.

How to Use Our System

Using our aquaculture system straightforward and easy. First, you need to set the system up in a suitable location. Once the system set up, you can fill it with water and start fish adding shrimp, or other aquatic creatures.

The system automated, which means the feeding, monitoring, and maintenance are all taken care of by the system. However, you still need to monitor the operational system and make sure everything working properly.

Service and Quality

We pride ourselves on the quality of our system and our commitment to customer service excellent. Our system built to last, and we use only the quality materials are highest in its construction.

In addition to our quality products, we also provide excellent customer service. We offer training and support ongoing ensure our customers are satisfied with their purchase and their system functioning properly.

Applications of Our System

Our aquaculture system has a wide range of applications in the food industry, including fish farming and aquaculture farming shrimp. It can also be used in education and research projects.

In fish farming production, feed cost is the largest part of the whole cost, basically accounting for about 60% to 70%. Therefore, saving feed cost is also a way to improve farming efficiency, but it must be based on reasonable and scientific methods. .

1. Choose feed with reasonable and balanced nutrients

The quality of the feed is directly related to the cost of breeding. If the quality of the feed is good, the digestible and absorbable part of the fish after eating is high, the growth rate of the fish is fast, and the feed coefficient is low. Conversely, raising fish with poor-quality feed will greatly increase the cost of farming.

2. Scientific and reasonable feeding is an effective way to reduce feed waste and control feed cost

Feeding should be based on the principles of "four determinations" timing, fixed point, qualitative and quantitative, so as to achieve a uniform and appropriate amount, and avoid sudden more and less, resulting in oversatisfaction, hunger, indigestion, and affecting the normal digestion and absorption of fish.

The feeding amount should be determined according to water quality, weather, fish activity and feeding status.

In terms of feeding amount, the fish are generally controlled to eat "80% full", that is, 80% of the fish are full, and 20% of the fish are not very full; after 2 hours of feeding, the feed is basically eaten, and there is a little leftover, or There are also a few schools of fish swimming around in search of food. This maintains the fish school's appetite and reduces feed loss.

Reasonable determination of feeding times should be determined according to the feeding habits, growth status and feeding strength of fish. Reasonable feeding amount and frequency are beneficial to improve the digestibility of fish to feed, reduce the loss of feed in water, and reduce the feed coefficient.

Properly grasp the feeding time and choose the feeding place. The feed table should be placed on the leeward side of the pond where the water is deeper, the bottom is harder, less leakage, and more open.

The time and frequency of feeding are determined according to the species of fish, feeding habits and size.

Generally, adult fish are fed twice in the morning and evening, preferably at 8-9 o'clock in the morning and 5-6 o'clock in the afternoon.

3. Healthy water quality management

Water quality management is very important, as the saying goes: 'Three minutes of species, seven minutes of management. ’ Pipe refers to water quality management. Pond water quality conditions have an important impact on fish feed coefficient.

Generally speaking, in water bodies with no pollution, fresh water, and sufficient dissolved oxygen, fish have a large food intake, strong appetite, high feed utilization rate, fast growth rate, and small feed coefficient.

Among the various physical and chemical factors of pond water quality, the amount of dissolved oxygen in the water body is the biggest factor affecting the feed. If the dissolved oxygen in the water body is sufficient, the growth and metabolism of the fish body will be vigorous, the digestion time for the feed will be greatly shortened, and the growth rate index of the fish will increase. coefficient is negative.

According to experiments by aquaculture experts, when the dissolved oxygen in water drops from 7.6 mg/ton to 3.1 mg/ton, the feed factor increases by 5.6 times, while the growth rate decreases by 9 to 10 times.

In addition, within a certain water temperature range, the consumption of fish feed is directly proportional to the increase in water temperature. Within a certain range of water temperature, for every 1°C increase, the feeding rate of fish with the same body weight will increase by 0.1% to 0.5%.

Therefore, the same fish size has different feeding rates at different water temperatures.

In the field of aquaculture, flowing aquaculture system is gradually emerging and becoming a highly anticipated aquaculture method. With its unique aquaculture concept and technology, it has brought new vitality and opportunities to the development of fisheries.

1. The principle and charm of flowing aquaculture system

Flowing aquaculture system, as the name suggests, is the high-density intensive breeding of fish in a fish pond with water flow exchange. Its core principle is to cleverly use the power of water flow to create an excellent living environment for fish. Usually, reservoirs, lakes, rivers, mountain streams, springs, etc. are used as water sources. With the help of water level differences, diversion or interception facilities and water pumps, water is allowed to flow continuously through the fish pond, or the discharged water is purified and re-injected into the fish pond. Water flow plays a vital role here. It not only continuously inputs dissolved oxygen to meet the breathing needs of fish, but also can promptly remove fish excrement, effectively maintain the good water quality of the pond water, and lay a solid foundation for the high-density intensive breeding of fish.

2. Various types of flowing aquaculture system

- Open flowing aquaculture system

- Normal temperature flowing aquaculture system: This is the primary form of flowing aquaculture system, which has many significant advantages. It requires a small investment, the pond construction process is relatively simple, and daily management is also quite convenient. It completely uses natural water sources, and the water temperature is not artificially adjusted. Since the discharged water is no longer reused, but new water is continuously injected, it can always maintain good water quality conditions. In the past, family-style fish farming in mountainous areas of my country, as well as temples and parks for raising ornamental fish, often adopted this method. After the 1970s, many fish species such as non-carp, carp, grass carp, roundhead bream, eel, and perch have successively become the objects of aquaculture under this form, and the scope of aquaculture has also expanded from simple edible fish farming to the breeding of fry and fish species. In normal temperature flowing aquaculture system, there is a key point, that is, under certain conditions, the flow rate and output are positively correlated. Therefore, making full use of the terrain difference when building the pond, so that the fish pond can obtain a large flow, and the water flow in and out of the fish pond does not require additional power, has become a key factor in determining whether this farming method has production value.

- Warm water: The outstanding feature of open warm water fish farming is the ability to regulate water temperature. It cleverly uses natural water sources with a temperature higher than the air temperature, such as hot springs, deep wells, or warm drainage from industrial and mining enterprises (mainly power plants), as the main water source or water source for regulation, and injects it into the fish pond together with natural room temperature water. By accurately controlling the flow of both, the appropriate temperature of the pool water can be maintained. This farming method has obvious advantages. It can not only increase the breeding density, but also significantly accelerate the growth and development of fish. In the low temperature season, it can keep the pool water at a temperature suitable for fish growth, thereby effectively extending the growth period of fish and shortening the breeding cycle. At the same time, it can also promote or inhibit the gonadal development of broodstock. In low temperature areas, using warm water to cultivate broodstock can advance the breeding period of broodstock, thereby increasing the feeding time of seedlings, creating favorable conditions for cultivating large-sized fish species.

Closed-loop flowing aquaculture system: Closed-loop flowing aquaculture sysytem is also known as circulating filtration fish farming. Its biggest feature is that the sewage discharged from the pond is purified and then injected into the fish pond again, so the total water consumption is greatly reduced compared with the previous two forms, and the water temperature can also be kept constant by heating. The basic technology of this farming method originated from aquariums. As early as the late 19th century, countries such as the Netherlands, the United States, and the United Kingdom began to use circulating filtration to treat water for fish farming, allowing the water to be reused for decades. In the 1960s, due to the pollution of waters in many countries and the increasing demand for live fish in the market, this farming method was gradually introduced into the field of seed breeding and edible fish production, and developed into a new farming process. In the circulating filtration fish pond, the discharged sewage contains harmful substances such as fish excrement and ammonia produced by the decomposition of residual bait, which will hinder the growth of fish, so it must be filtered and purified before reuse. The general treatment process is to aerate the discharged sewage first, then settle it, and remove suspended solids such as fish feces, leftover bait and debris. Then, use a biofilter or a biorotor for biological purification. The biofilter further clarifies the water by blocking some suspended matter remaining in the water in the gaps of the filter material (pebbles, yellow sand, plastic particles, mesh, etc.) or depositing it on its surface. At the same time, with the help of the microbial community (biofilm) growing on the surface of the filter material, the ammonia and nitrite dissolved in the water are oxidized into non-toxic substances to complete the sewage purification process. The biorotor uses the microbial community growing on the surface of the disc (cylinder) to oxidize the organic matter in the water. The purified water is then aerated and enters the fish pond. If it is a warm water circulation filtration system, it is also necessary to use steam or hot water boilers for heating after filtration. During the whole process, the water quality needs to be strictly monitored and managed according to the standards. In addition, due to the high density of fish farming under this breeding method, it is necessary to feed granular bait with comprehensive nutrition to prevent fish from nutrient deficiencies and avoid bait loss. Moreover, in the circulating filtration fish pond, the occurrence and transmission speed of fish diseases are extremely fast, so a strict epidemic prevention system must be established. Once fish diseases are found, the sick fish must be isolated and treated quickly, and the entire system must be disinfected. The area of closed circulation fish ponds is usually small, generally only a few square meters to dozens of square meters, and most of them are built indoors. The entire device covers multiple parts such as the fish pond system (fish pond and inlet and outlet pipes, etc.), purification system (sedimentation tank, filter tank), water supply system, air supply system, heating system, etc., and is centrally controlled and modernized through the control and monitoring system. This highly integrated and intelligent management method makes it have a strong control ability over the fish farming environment and a large production potential, especially suitable for the breeding of excellent fish and precious fish. It has extremely high use value in large cities, industrial and mining areas or areas lacking sufficient water sources. However, its construction cost is expensive, the technical level of management is high, and the energy consumption is also high.

3. Significant advantages of flowing aquaculture system

- Excellent water quality: Continuously flowing water continuously brings sufficient dissolved oxygen to the fish pond, while taking away fish excrement and leftover bait in time, effectively preventing water quality deterioration, greatly reducing the risk of fish disease, and providing a clean and healthy growth environment for fish. For example, in some fish farms that adopt flow-through aquaculture, the incidence of fish has decreased by [X]% compared with traditional pond aquaculture.

- Fast growth: Good water quality and sufficient dissolved oxygen enable fish to grow in a more suitable environment, accelerate metabolism, and significantly increase growth rate. Taking rainbow trout as an example, under flow-through aquaculture conditions, its growth cycle is shortened by [X] months compared with ordinary aquaculture methods, and the output is also greatly increased.

- High-density aquaculture: Flow-through aquaculture creates conditions for high-density aquaculture, greatly increasing the aquaculture volume per unit area, and effectively improving the utilization efficiency of land and water resources. According to statistics, in the same area of aquaculture area, the output of flow-through aquaculture can be increased by [X] times compared with traditional pond aquaculture.

- Precise management: With the help of modern monitoring and control technology, key factors such as water flow, water temperature, dissolved oxygen, and feeding can be precisely controlled to achieve scientific breeding and improve breeding efficiency. For example, sensors are used to monitor water quality parameters in real time, and water flow and oxygenation equipment are automatically adjusted to ensure that fish are always in the best growth state.

- Looking forward to the future of flowing aquaculture system

With the continuous advancement of science and technology and the growing demand for the quality and quantity of aquatic products, flow-through aquaculture will usher in a broader space for development. On the one hand, in terms of technological innovation, the aquaculture equipment and management system will be further optimized to improve the intelligence and automation level of aquaculture. For example, artificial intelligence technology will be used to achieve real-time monitoring and precise control of water quality and fish growth conditions, develop more efficient water treatment technology and feed formula, reduce aquaculture costs, and improve aquaculture benefits. On the other hand, in terms of sustainable development, flowing aquaculture system will pay more attention to ecological environmental protection, and reduce the waste of water resources and pollution to the environment by optimizing the aquaculture model. At the same time, it will strengthen the integration and development with other industries, such as combining with tourism and leisure agriculture, develop more distinctive fishery products and services, and enhance the added value of the industry. In addition, with the continuous increase in global demand for aquatic products, flowing aquaculture system is expected to play a greater role in the international market and promote the international development of fisheries.

As an efficient, environmentally friendly and sustainable farming method, flowing water aquaculture is leading the aquaculture industry into a new stage of development with its unique advantages and charm. It not only brings higher economic benefits to farmers, but also makes positive contributions to ensuring food safety and protecting the ecological environment. I believe that in the future, flowing water aquaculture will continue to innovate and develop, bringing more surprises and well-being to people.